Diamond X-Ray Lens

Diamond x-ray lenses are now commercially available from PALM Scientific.

Recent testing at the ESRF demonstrated performance comparable with industry standard beryllium lens in terms of shape accuracy.

- <1 um figure error is achieved for R100um lens

- Sa polished ~ 25nm

- Sa unpolished ~200nm

- Radius of curvature: from 30um to 8mm

- Standard (12mm) and custom packaging available

“Polished Diamond X-Ray Lenses“. Celestre, R., et. al. J. Synchrotron Rad. 29, 629-643.(2022)

Why Diamond?

As noted by Serebrennikov et al. (2016), diamond lenses are the material of choice for X-ray lenses at higher X-ray energies, i.e. above 30 keV, when the advantage of higher transmission and larger effective aperture of Be lenses decreases. Using diamond and keeping the lens radius equal, only about half the number of lenses are required. At lower energies, diamond lenses have strong potential for applications where the lenses are subjected to high powers or intense short duration X-ray pulse energies.

From: “Optical performance of materials for X-ray refractive optics in the energy range 8–100 keV“. Serebrennikov, D., Clementyev, E., Semenov, A., & Snigirev, A. . JСР, 23(6), 1315–1322 (2016).

Polishing

The polishing process is a hybrid of chemical etching and free abrasive polishing. Multiple parameters were optimized: polishing bit material, slurry solvent and grit size, contact pressure, and rotational speed.

- Measured at 50X magnification with lens curvature subtracted

- Surface roughness, Sa polished ~ 25nm

- Surface roughness, Sa unpolished ~200nm

The polishing process has been fine-tuned and is able to maintain a quasi-uniform removal rate along the complete surface of the lens.

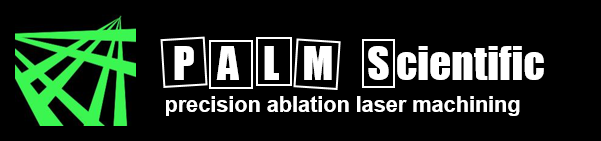

X-Ray Focusing Comparison with Beryllium

“Using a 2D detector with high spatial resolution, we recorded the transverse X-ray beam profile in the vicinity of the focal plane, when using each of the lens stacks polished diamond and beryllium. The experiment was performed on ID06 using a 10 keV beam.“

“Focusing capabilities and lens figure errors are very close to those obtained by equivalent Be lenses. We measured the figure errors of the diamond lenses of 1 mm r.m.s. over the full useful lens aperture of almost 400 mm”.

From: “Polished Diamond X-Ray Lenses“. Celestre, R., et. al. J. Synchrotron Rad. 29, 629-643.(2022)

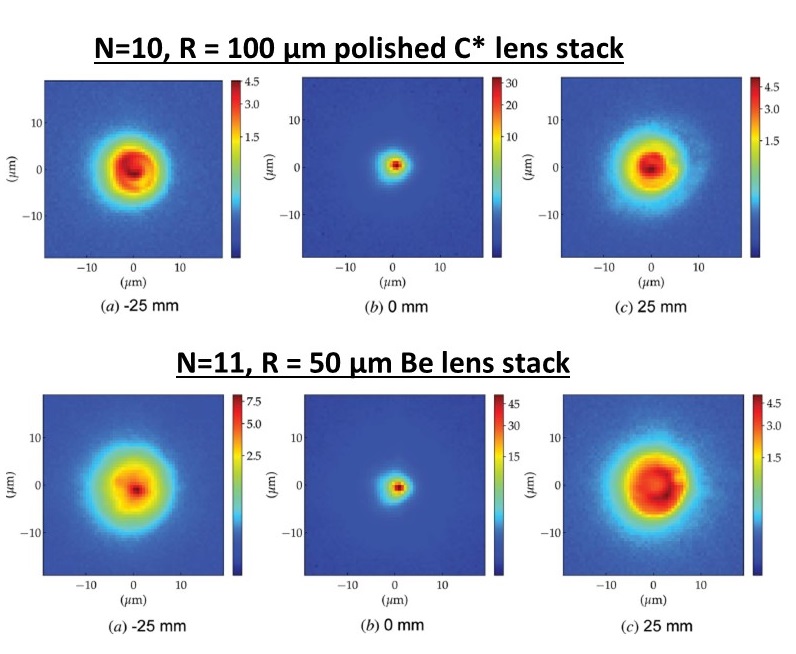

X-Ray Metrology Comparison with Beryllium

“The performance of these lenses is comparable to that of commercial Be lenses, which are regarded as the standard due to their widespread use and continuous development dating back to 2002“.

“… the figure errors of the diamond lenses (unpolished and polished) are slightly lower than those of commercial Be lenses.

Although the mechanical polishing does slightly increase the nominal figure error and more significantly its dispersion, they are still close to the values measured on the commercial Be lenses“.

From: “Polished Diamond X-Ray Lenses“. Celestre, R., et. al. . J. Synchrotron Rad. 29, 629-643.(2022)

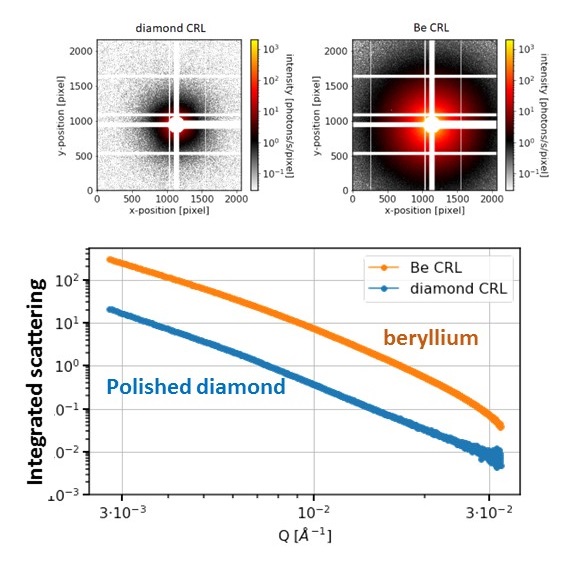

SAXS background

“The low X-ray scattering produced by diamond CRLs is one of its very attractive features, that may allow to extend the range of applications of the CRL optics to the areas / experiments that are very sensitive to background scattering (e.g. where coherent diffractive imaging reconstruction of weakly-scattering samples is performed), where Be lenses are not currently used, or are not considered as the optics of best choice”

From: “Analysis of hard x-ray focusing by 2D diamond CRL” O. Chubar, et. al., SPIE conference proceedings 2020, https://doi.org/10.1117/12.2568980